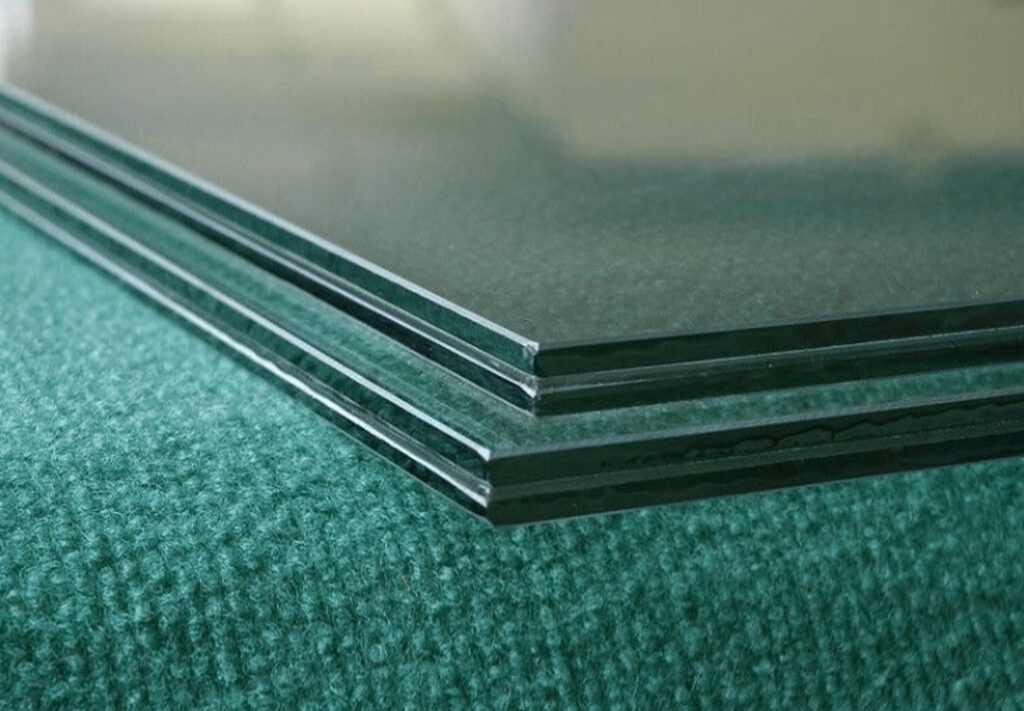

It is the name given to the glass obtained as a result of combining two or more glass plates using PVB (Polyvinyl Butyral) through heat and pressure. PVB is a kind of resin used in areas that require special applications such as strong bonding, optical clarity, adhesion to many surfaces, durability and flexibility.

PVB, which is also a protective layer, is in a very flexible form and when combined with glass layers, it gains a completely transparent appearance. This polymer layer is quite durable. For this reason, even if the glass is broken, the breakage that occurs on any of the glass plates does not affect the other plate and keeps the broken pieces on it and prevents it from falling.

The main application area is safety and automobile glass.

The desired appearance is obtained by choosing various colors and thicknesses in the glass and intermediate layers. Laminated glass is also commonly known as ‘Safety Glass’. Laminated glasses are used in places that will pose a risk in terms of security, in showcase glasses, in stair railings, in glass floors such as winter gardens, in areas such as aquarium glasses. Laminated glass thicknesses are up to 6+6 12 mm thick, with 2mm+2mm glass combination.

In addition to this feature, it also provides sound insulation. Higher strength is achieved by applying tempering process to laminated glasses.